Your cart is currently empty!

Extend the Life of Your Equipment A Guide to Maintaining Rubber Flexible Cables

Introduction

Rubber cables are flexible, and can be curved to suit a range of applications in different industries.

They ensure uninterrupted flow of current; this is seen when they power machinery in factories or supply electricity to homes.

Such machines must also be taken care of so that they can work efficiently and serve the owners for many years without being replaced prematurely.

In this article, we will focus on rubber flexible cable as well as giving maintenance tips so that you can maintain their lifespan.

This will help you keep your electrical system safe and efficient while getting maximum return on investment.

Understanding rubber flexible cable

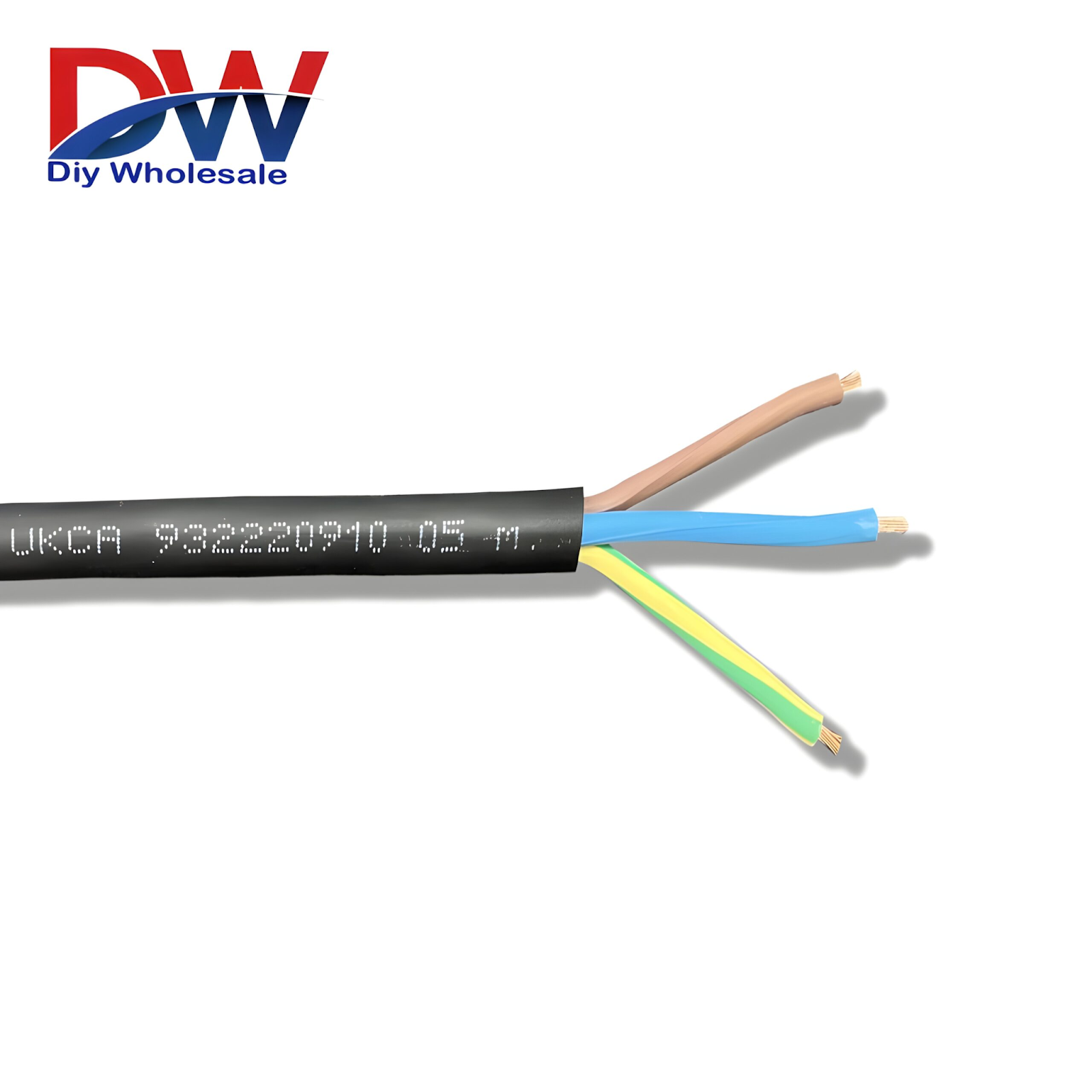

Before we touch on the methods of maintaining these cables, let’s first look into their basic constructions.

Commonly these contain:

- Conductors: These are the wires within which the electric current flows. Mostly made from either aluminum or copper.

- Insulation: The enclosing part for conductors with insulation materials to avoid loss of current through conduction. PVC, EPDM (ethylene propylene diene monomer) and silicone rubber are commonly used insulating materials for rubber flexible cables.

- Jacket: It acts as an outer protective layer for the cable against physical injuries, environmental conditions and chemicals to some extent that damages it also more often than not it is made out of the same substance with insulation.

Factors affecting the Life-span of rubber flexible cable:

There are a number of factors that determine how long rubber flexible cables last.

Take note if these:

- Mechanical Stress: Regular bending, twisting or flexing can exert pressure upon internal components leading to conductor breakage or insulation damage.

- Temperature: The insulator jacket or covering may deteriorate because of extreme temperatures both hot and cold ones.

- Sunlight And Ozone Exposure: This could make them brittle hence crack under sunlight exposure in direct sunlight or ozone influence.

- Chemical Exposure: Some chemicals react with rubber thus accelerating its degradation process

- Electrical Overload: Exceeding the capacity at which it carries its current may result in overheating or even cause fire explosions.

Practical Tips on Maintaining rubber flexible cable

Having understood these factors affecting their lifespan, the following are various tips to help you maintain your rubber cables;

- Proper Handling and Storage:

- Do not bend, twist or pull the cables excessively.

- Store them in a cool dry place free from direct sunlight and ozone

- When not in use, loosely coil the cable so as to avoid it from twisting itself into knots or causing strain on the conductors.

- To avoid crushing or damaging them, keep them off of the ground by using cable reels and hangers.

- Regular Inspection: Check rubber flexible cable occasionally for signs of damage such as cracks, cuts, discoloration, loose connections among others. Pay closer attention to areas where the cable is bent or experience stress.

- Cleaning: Keep rubber flexible cable clean by making sure they are free from dust/dirt and debris. Occasionally wipe them down with a dry cloth. Avoid solvents or any harsh chemicals that can destroy insulation or jacket material.

- Strain Relief: At cable terminations (points where the cable connects to equipment), install appropriate strain relief mechanisms so that there is no excessive pulling or stress on internal components.

Cable clamps, tie wraps and specialized strain relief fittings can be used to achieve this objective.

- Mind The Temperature: Ensure that they operate within their specific temperature limits; exposing them to too much heat or cold accelerates their lifespan closure periods prematurely.

- Chemical Compatibility: To prevent degradation during chemical processes always check if your cable has chemical resistance. The manufacturer’s specifications indicate what type of cable should be used with different chemicals.

- Maintenance Records: Keep a record of all cable inspections, cleaning, and repairs. This also enables one to monitor them over time and identify possible problems in advance.

Conclusion

Just do these practical tips into your standard maintenance routine and you will prolong the life of your rubber flexible cable. As a result, you will avoid the cost of purchasing new ones besides maintaining safe and efficient electrical systems within your premises.

Remember however that prevention is key in this regard. On the other hand, should you adopt measures above to look after your cables; you will avoid expensive downtimes, possible electrical hazards, and keep your equipment running smoothly for years.

Leave a Reply