Complete Guide to Uses and Specifications of 2.5mm Twin & Earth Cable

Introduction

The twin & earth cable is regarded as one of the most important parts of any modern electr...

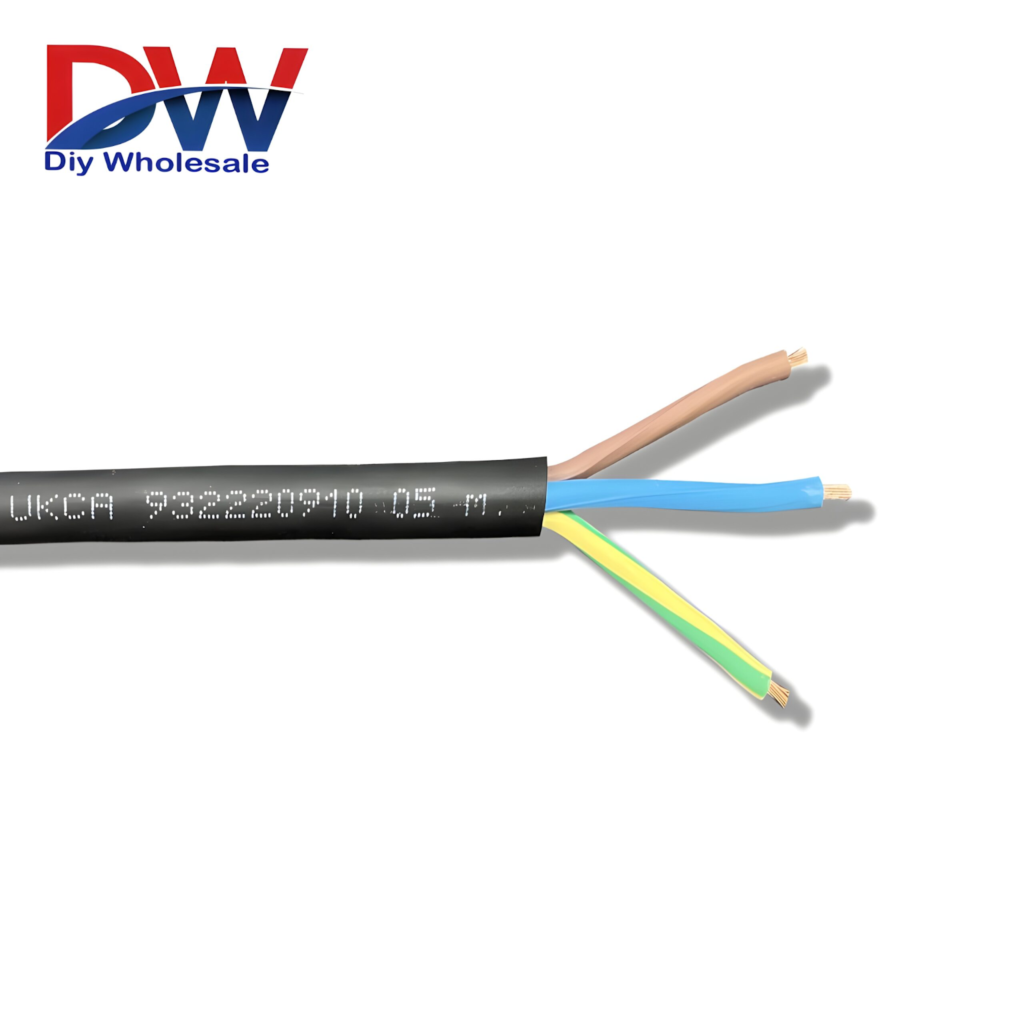

Learn the differences between black rubber cables & TPE cables | Comprehensive Guide

Introduction

For electrical and electronic cabling to function reliably, efficiently, and for a long time, ...