Complete Guide to Uses and Specifications of 2.5mm Twin & Earth Cable

Introduction

The twin & earth cable is regarded as one of the most important parts of any modern electr...

Learn the differences between black rubber cables & TPE cables | Comprehensive Guide

Introduction

For electrical and electronic cabling to function reliably, efficiently, and for a long time, ...

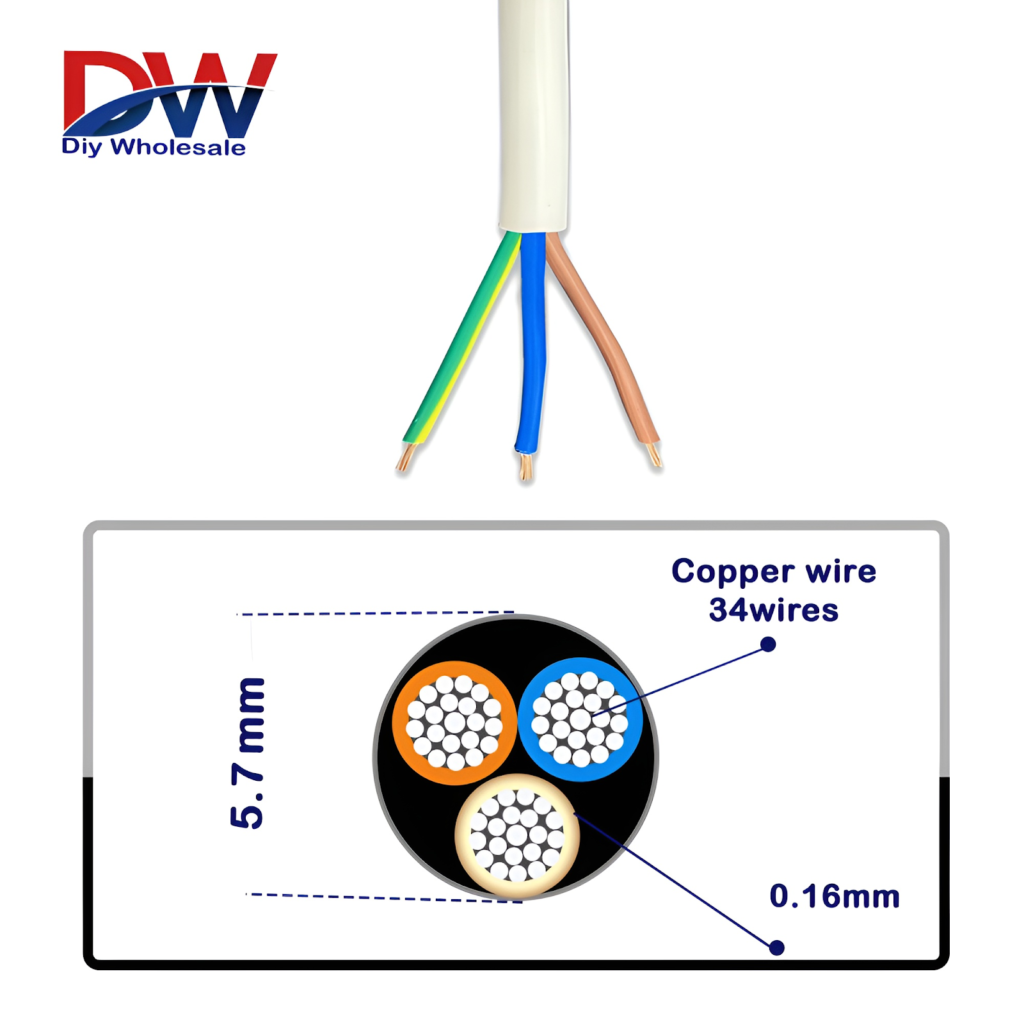

Understanding the Versatile Applications of 3183Y Cable for Enhanced Safety and Efficiency at Home

Introduction

If you want to improve the safety and efficiency of your home's electrical system, you must fi...

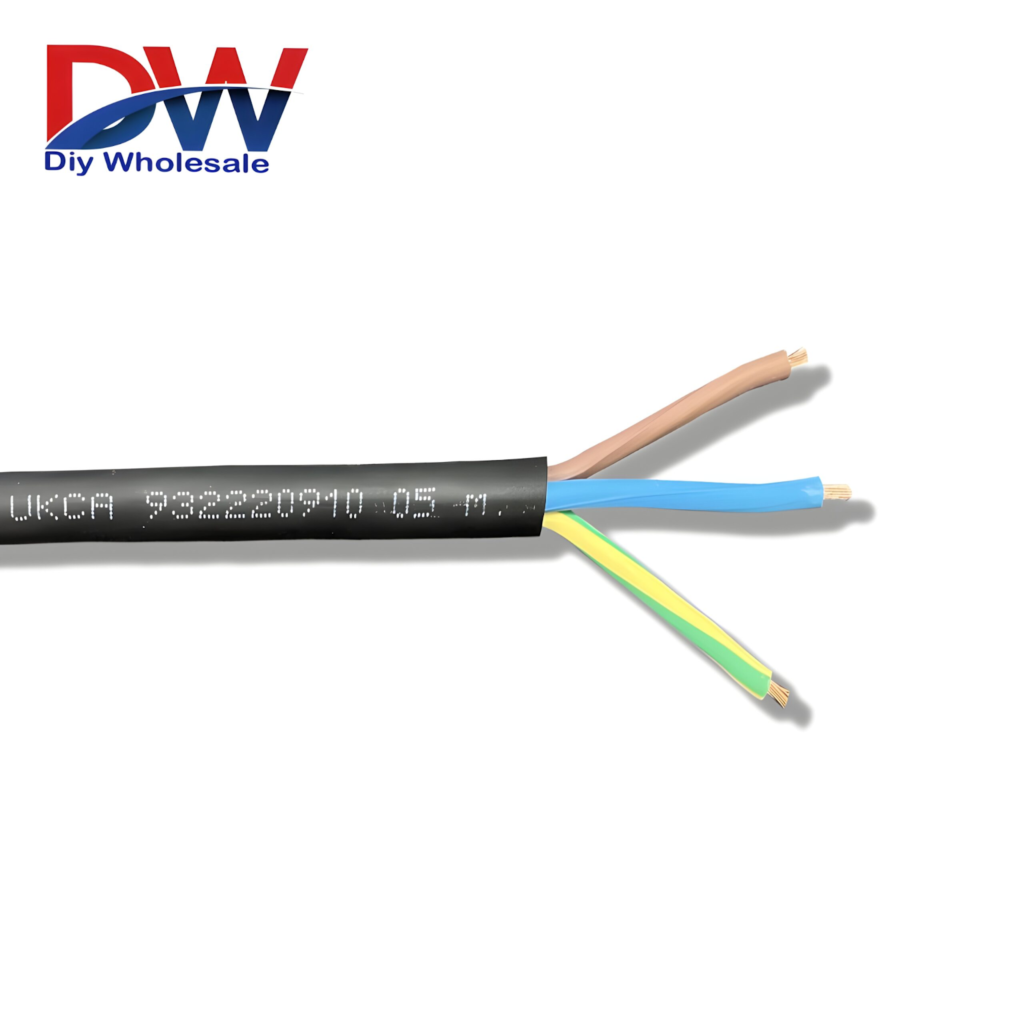

Discover the Versatility of Black Rubber Flex Cable for Safe Electrical Wiring

Introduction

Black rubber flex cable, also known as black rubber cable or 3 core rubber flexible cable, is...